Jan Petrik

Freelance hardware engineer with more than decade of experience in hardware design.

I have gained my experience working mostly in medical, aerospace and automotive industries. I am passionate about analog electronics, power supplies and power integrity, EMC and circuit simulations. I enjoy figuring out complexities of quality hardware design, that stand the tests of EMC chamber, mass production and time. Since 2021, I’m offering consultancy, custom hardware development and engineering training.

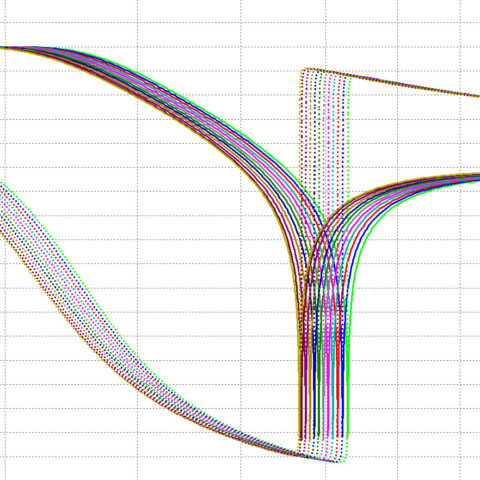

Tolerance Analysis:

A Hands-On Training

You have been selling and producing a successful product for some time. Now out of blue, the latest batch does not pass manufacturing testing. Not by a lot, but not by a little either. Production is halted, and everyone scrambles to investigate…

An elusive malfunction of your product emerges. Sending a technician and replacing the main PCB helps. Malfunction PCB tested good in your production tester. Described issue is impossible to replicate. It is not a widespread issue, one or two reports here and there…

During the final product testing, the device fails. All the subsystems passed their respective testing with flying colors. Sometime running the test many times helps. Sometimes you need to shuffle subsystem PCBs around to find a working combinations…

Make sure your product fulfils requirements across temperature range and manufacturing variance. Improve quality and reliability of your product with tolerance analysis. Are your test limits guesstimated, or designed?

areas of expertise

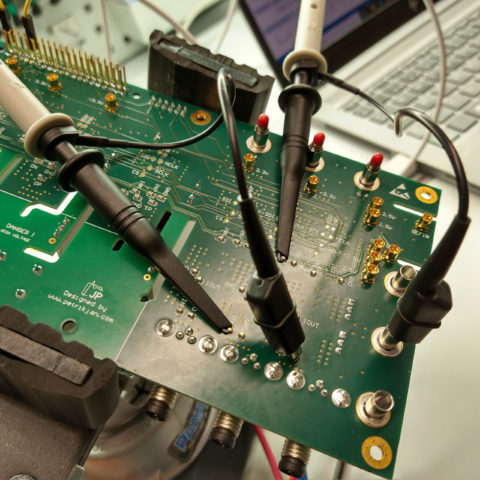

HW design

Analog, Mixed and Digital

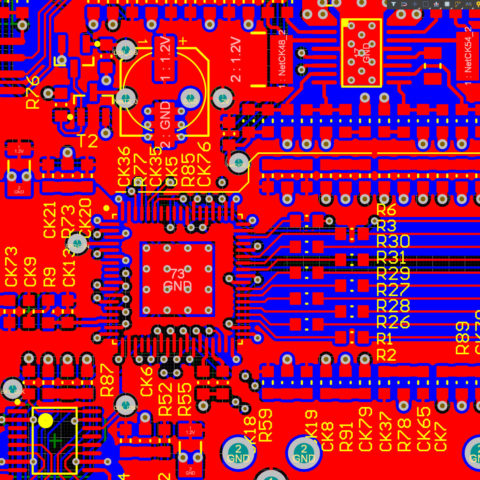

PCB Layout

With Altium Designer

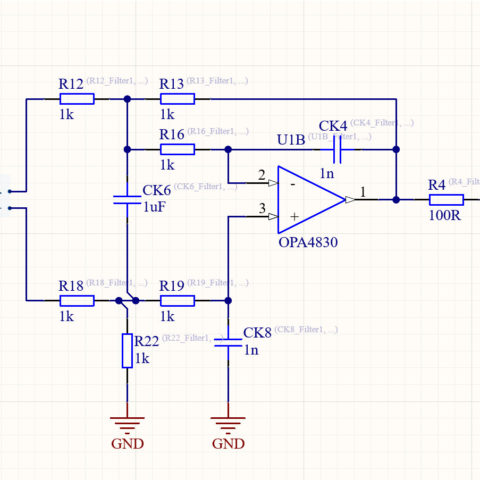

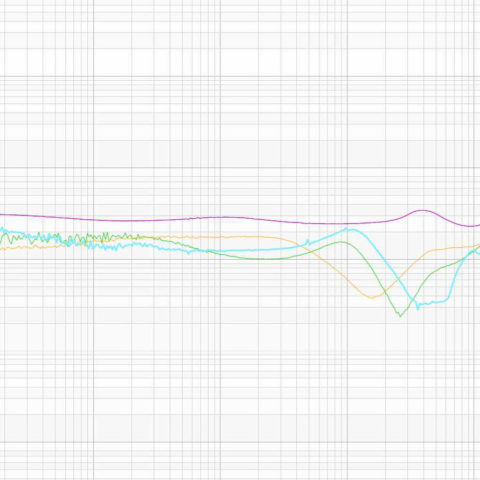

simulation and modelling

in Spice

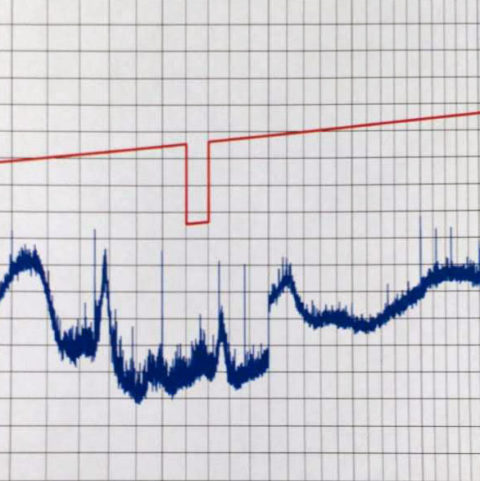

Power integrity

Design and Measurements

EMC

Integral part of my development efforts

DFx

For ease of testing and volume production